Bracing Rack Roll Forming Machine

Bracing Rack Roll Forming Machine

Introduction

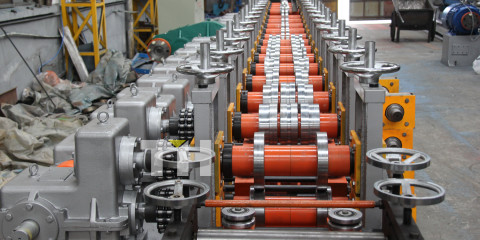

Bracing Rack Roll Forming Machine consists of de-coiler, main roll forming, straightening device, hydraulic punching device, fly saw cutting device, out table and control box. The machine is fully automatically controlled by PLC touch screen. Machine running speed is 0-15m/min, adjustable according to the cutting length.

Technical Parameter

- Material thickness: 1.2mm-2mm

- Roller stations: 11 stations

- Roller material: Cr12, HRC58-62°,chrome plated

- Shaft diameter:Ф50mm,material 40Cr

- Main motor power: 11Kw

- Forming speed: 0-15m/min

- Drive way: drive by gearbox

- Machine size: 18000mm(L) x 1100mm (W)

- Machine weight: about 7 tons

Related Profiles for Racking Solution

Boltless Shelving, upright post, step beam, Drawer Racking, Drive-in Racking, Push Back Racking, Live Racking, Mobile shelving, Cantilever Racking, Multi-tier Racking, Carton Flow Racking, gravity racking, long-span racking, slotted angle shelving, rivet shelving, rack mezzanine, stacking racking, etc.

Application

Bracing rack roll forming machine is used to produce pallet bracing rack( also known as bracing bolted rack, posts and braces), which is designed for long span shelving or wide span shelving, these heavy duty steel rails connect to the teardrop upright to form a secure level of pallet storage. Depending on the customers’ specific requirements, the racing rack can be either pre-notched and pre-cut, then roll formed, or notched and roll formed with post cutting to length. Reviewing the customer’s production needs, Taihu Machinery can evaluate what solution may fit best.